Posted on March 9, 2005

Introduction

I've been modding computers for a while now, with my first computer being the standard window, neon, and intake fan, back when modding was just becoming popular. The idea of this case came from looking at all those modded cases with multitudes of fans for added air flow, and thinking how about making the ultimate cooled case just out of fans. The board that was used was obviously a Mini-ITX board, the great VIA EPIA M which is a mere 170 x 170 mm. It was decided that 80 mm fans were the way to go since they would fit nicely around the board, with only a 10 mm gap to fill between the fans.

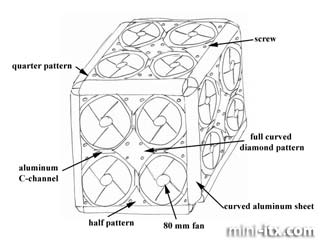

An initial sketch was drawn of the case. Aluminum C-channel was planned to be used to fill in the 10 mm gap and it was easily obtainable from my local hardware store. To secure the fans and C-channel; aluminum sheet would be cut in a curved diamond shape and screwed in place. This same curved diamond shape was planned for the corners and center sections which were quarters and halves respectively. The edges were initially planned to be curved aluminum sheet.

|

Initial design, excuse the shoddy drawing.

Case construction

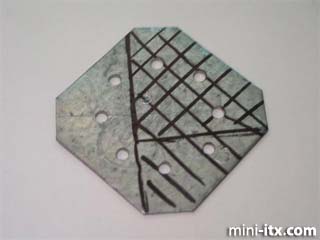

The first thing was to find some fans, Duh!. 20 identical secondhand 80 mm fans were found on ebay extremely cheap, when received they looked like they had minimal use with hardly any dust on them. They did come with fan screws, though they where all different varieties which would not have worked with the symmetrical design I had planned. It was decided to buy screws for the fans, and to use them as a feature giving an industrial look. Next was a trip to the local hardware store to pick up some supplies. Some 12 mm C-channel, 0.5 mm thick aluminum sheet and a 100 pack of round head screws were bought. The initial idea was for a curved diamond shape in the center, but it was changed to an octagon shape since it was a lot easier to cut straight edges then curved.

|

A template was constructed from steal with screw holes to make the job a lot easier, with half and quarter segments marked. In total 45 segments were needed to complete the case.

|

The first face created showing the octagonal shape in the center attached with screws. The screws were screwed directly into the C-channel making the job easier. The aluminum sheet was extremely easy to cut with standard scissors, though this also made it quite susceptible to getting out of shape.

|

Two more faces completed, and hence the very basic shape is created. The other two sides excluding the base were slightly more complicated, because of the motherboard back faceplate and the DVD rom drive.

|

For the base It was decided to use 25 mm MDF spray painted black to mimic the look of fans. The base was lightly larger then the motherboard.

|

A hacked up motherboard tray from an old ATX case would be screwed onto the wood and then the motherboard attached. This was thought to be easier then screwing the motherboard directly into the wood, since it allowed the board to be removed easily and it didn't require any precise drilling.

It was decided that curved edges would be too complicated to implement, so a straight edge design which only required two bends was used and this matched the octagon patterns design. The first four edges were easy to attached to the base by just extending one side so it overlaps the bottom of the wood and then screwed into place.

|

|

|

Quick Links

Mailing Lists:

Mini-ITX Store

Projects:

Show Random

Accordion-ITX

Aircraft Carrier

Ambulator 1

AMD Case

Ammo Box

Ammo Tux

AmmoLAN

amPC

Animal SNES

Atari 800 ITX

Attache Server

Aunt Hagar's Mini-ITX

Bantam PC

BBC ITX B

Bender PC

Biscuit Tin PC

Blue Plate

BlueBox

BMW PC

Borg Appliance

Briefcase PC

Bubbacomp

C1541 Disk Drive

C64 @ 933MHz

CardboardCube

CAUV 2008

CBM ITX-64

Coelacanth-PC

Cool Cube

Deco Box

Devilcat

DOS Head Unit

Dreamcast PC

E.T.PC

Eden VAX

EdenStation IPX

Encyclomedia

Falcon-ITX

Florian

Frame

FS-RouterSwitch

G4 Cube PC

GasCan PC

Gingerbread

Gramaphone-ITX-HD

GTA-PC

Guitar PC

Guitar Workstation

Gumball PC

Hirschmann

HTPC

HTPC2

Humidor 64

Humidor CL

Humidor II

Humidor M

Humidor PC

Humidor V

I.C.E. Unit

i64XBOX

i-EPIA

iGrill

ITX Helmet

ITX TV

ITX-Laptop

Jeannie

Jukebox ITX

KiSA 444

K'nex ITX

Leela PC

Lego 0933 PC

Legobox

Log Cabin PC

Lunchbox PC

Mac-ITX

Manga Doll

Mantle Radio

Mediabox

Mega-ITX

Micro TV

Mini Falcon

Mini Mesh Box

Mini-Cluster

Mobile-BlackBox

Moo Cow Moo

Mr OMNI

NAS4Free

NESPC

OpenELEC

Osh Kosh

Pet ITX

Pictureframe PC

Playstation 2 PC

Playstation PC

Project NFF

PSU PC

Quiet Cubid

R2D2PC

Racing The Light

RadioSphere

Restomod TV

Robotica 2003

Rundfunker

SaturnPC

S-CUBE

SEGA-ITX

SpaceCase

SpacePanel

Spartan Bluebird

Spider Case

Supra-Server

Teddybear

Telefunken 2003

TERA-ITX

The Clock

ToAsTOr

Tortoise Beetle

Tux Server

Underwood No.5

Waffle Iron PC

Windows XP Box

Wraith SE/30

XBMC-ION